Textile microperforated ducts

Textile microperforated duct: lightness and practicality

The first microperforated ducts were made of fabric. To date, this material is still the most widely used for such ducts, covering more than half of the world market for microperforated ducts. OneAir uses the best fabrics and fibers available, technologically advanced, in continuous collaboration with suppliers for a constant development of new products that meet the needs of the market. Ideally eliminating any producible diameter and length limits, textile micro-perforated ducts provide many advantages.

The textile line is also the answer to the application needs that require light but resistant materials due to the possibility of frequent maintenance and washing. In fact, these micro-perforated ducts can be installed safely in environments where it is necessary to disinfect frequently, being easily washable. The possibility to choose from a wide variety of fabrics and colors allows their adaptability to any type of installation.

Configuration

➤ Any length possible thanks to the modular system

➤ Modules of variable length joined with zip

➤ Available diameters from Ø200mm to Ø2.000mm

Customization

➤ Logo application by label

➤ Antibacterial treatment

➤ Anti-static treatment

➤ Custom printing

Available fabrics

OneLight. 100% P.E.; 75g/m²; B s1 d0

OneFiber. Mineral fiber 100%; 480g/m²; A1

OneClass. 100% P.E.; 180g/m²; B s1 d0

OneClean. Food areas; 100% P.E.; B s1 d0

OnePremium. 100% P.E.; 240g/m²; B s1 d0

The fabric approved B s1 d0 is certified OEKO TEX 100 Standard, this confirms that all tissues used have not received treatments harmful to human health and that the dyes used for dyeing are not toxic.

Laser cutting of the holes cancels the release of volatile particles from the fabric during the operation of the diffuser making the product completely safe for this use.

Available colours

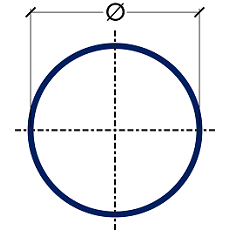

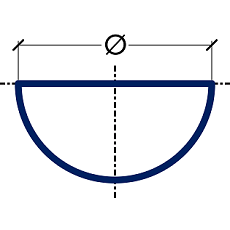

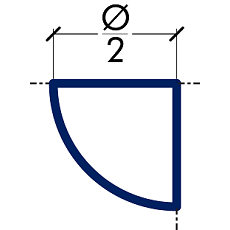

Available shapes

Circular

Semicircular

Quarter circular

Features and benefits

Lightness. OneAir’s high-tech fabrics have weights between 75 to 480g/m², ensuring durability and longevity combined with a low weight: a diffuser of a typical installation weighs only 10kg including the mounting system so there is no burden on the structure of the building.

Safety. In case of failure of the system, the lightness and softness of the fabric does not cause any damage to any occupants of the room.

Quick installation. The agile suspension system, combined with the lightness of the fabric, significantly reduces installation time and the consequent cost of labor.

Simple maintenance. Textile diffusers are easy to wash when necessary and this allows planned maintenance at certain costs. The fabrics are waterproof for better hygiene but also for precise control of air diffusion and total absence of condensation.

Economical. Textile diffusers represent the best compromise between effectiveness, aesthetics and savings. Their lightness and handling allows you to use easy transport formulas and therefore less expensive.

Consult the technologies that best allow your project to achieve maximum efficiency in the environment

We design and manufacture innovative air diffusion systems. With our commitment to research and development of new HVAC solutions, we have perfected the know-how to bring air distribution to a whole new level: the progress is realized in the design of systems with variable geometry but also in proposals for new solutions.